Modern metalworking is all about speed, precision, and efficiency. As demand grows, fabrication shops are looking for new ways to produce high-quality work faster. The key to staying competitive lies in upgrading to advanced metalworking machinery that enhances both fabrication speed and material handling. This guide explores the benefits of integrating modern equipment into your workflow and how it can transform your operations.

How does modern machinery increase fabrication speed?

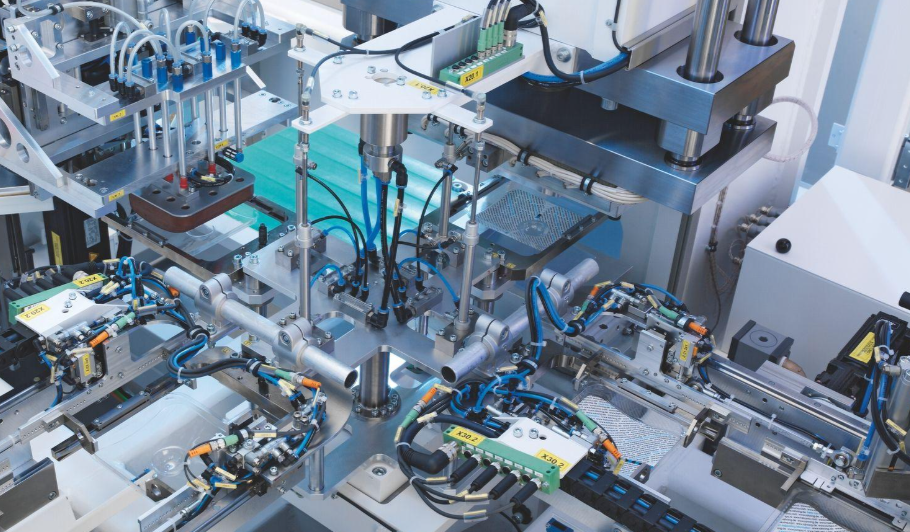

Advanced metalworking machinery is engineered to significantly cut down production times. Traditional methods often rely on manual labor, which can be slow and prone to error. Modern machines, on the other hand, incorporate automation and powerful technologies to perform tasks with incredible speed. For example, automated laser cutters and plasma cutters can slice through thick metal sheets in a fraction of the time it would take manually. Similarly, robotic welding systems can complete complex welds with consistent quality, operating around the clock without breaks. This level of automation means projects are completed faster, allowing shops to take on more work and increase their output.

What is the role of machinery in improving material handling?

Efficient material handling is just as important as the fabrication process itself. Moving heavy sheets of metal, positioning parts for welding, or transporting finished components can be time-consuming and physically demanding. Modern material handling systems, such as automated conveyors, robotic arms, and magnetic lifters, streamline these processes. These systems reduce the need for manual lifting, which not only speeds up the workflow but also improves workplace safety. By automating how materials are moved and positioned, businesses can ensure a smooth, continuous production flow, eliminating bottlenecks and minimizing downtime between fabrication stages.

What are the key benefits of upgrading metalworking equipment?

Investing in new metalworking machinery offers a wide range of advantages beyond just speed. One of the most significant benefits is the improvement in accuracy and consistency. Automated systems can replicate tasks with a high degree of precision, ensuring that every part meets exact specifications. This reduces material waste from errors and rework.

Another benefit is enhanced safety. Automated material handling and enclosed machining processes minimize direct human contact with heavy materials and dangerous operations, leading to fewer workplace accidents.

Finally, modern machinery provides greater flexibility. Many new systems are programmable and can be quickly adapted to handle different designs and materials. This allows fabrication shops to easily switch between jobs and respond to diverse customer demands without lengthy setup times.

How does better machinery impact business growth?

By boosting fabrication speed and efficiency, modern metalworking machinery directly contributes to a company’s bottom line. Faster production cycles mean quicker project turnaround, which enhances customer satisfaction and encourages repeat business. Increased capacity allows a shop to take on larger or more numerous projects, opening up new revenue streams.

Furthermore, the reduction in labor costs for repetitive tasks and the decrease in material waste lead to lower operational expenses. These savings can be reinvested into the business for further growth, whether it’s through acquiring more advanced technology, expanding the workforce, or exploring new markets. Ultimately, embracing modern machinery is a strategic move that builds a more productive, profitable, and competitive fabrication business.

Your Next Steps

Upgrading your metalworking machinery is a crucial step toward improving fabrication speed and material handling efficiency. By investing in modern automation and technology, you can increase your output, reduce costs, and create a safer work environment. The result is a more competitive business poised for long-term growth and success in a demanding industry.